A graphical LEAN tool to visualize, quantify and optimize factory layout design based on global flow analysis

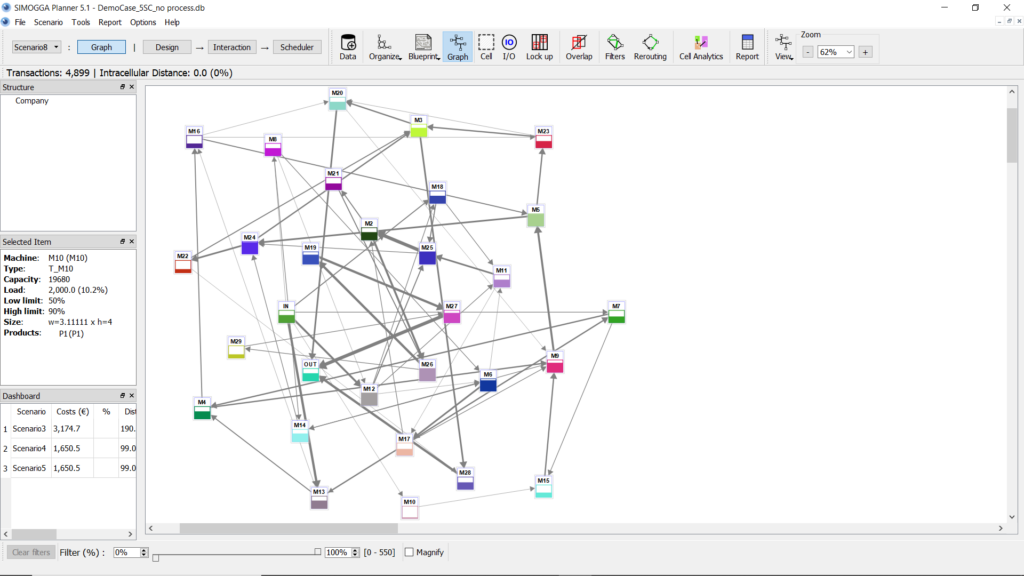

Spaghetti Diagram

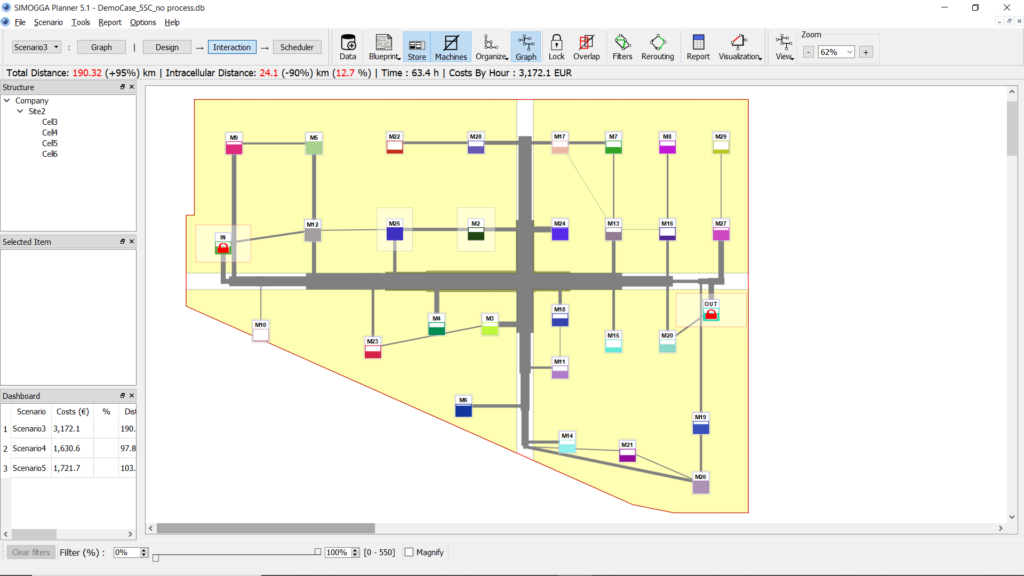

Flow by aisles

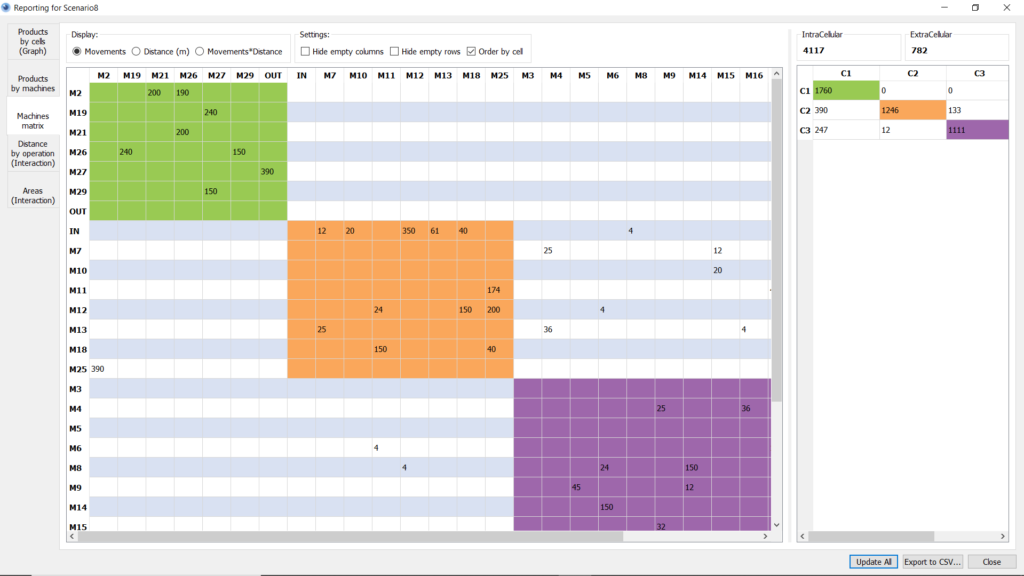

Cells creation

Decrease traffic within the production unit by 10 to 30%

Collaborate information about the factory’s production

Awaken the reactivity to market demands

Decrease Workload in the factory by creating product families

Benefits for Lean Team

- From macro to micro: set global data and progressively increase the granularity (Start with a few amount of data)

- Accelerate management decision-making process

- Support the Lean Methodology by automatically analyzing the Spaghetti Diagram and Dynamic VSM

- Support Quick Response Manufacturing (QRM) methods by defining the product families and forming the cells to manage the factory (Cellular Manufacturing) easily

- Support Systematic Layout Planning (SLP) by simplifying the process of layout creation (Site, blow-ck and detailed layout) in all-in-one

- Eliminate waste during production and reduce Lead Time

- Increase overall plant productivity

Benefits for Logistic Team

- Analyze the different flows (products, operators, supply, waste…)

- Reduce distance traveled by personal or material handling

- Simulate the plant throughput

- Reduce inventory

- Easy to use, easy to understand and allow a collaborative approach

In the showcased video, we quickly describe the process used to design the factory in the tool and reorganize the layout optimally.

If you want more information or to fully understand how to solve a case with SIMOGGA, we recommend you watch one of our video tutorials.

More About SIMOGGA Layout Design

Environment

- Discreet production environment

- High mix, low volume

- Great complexity (in process and flow)

- Integrating a significant human capital component (high expertise)

Features

- 2D factory layouts to facilitate the understanding

- Multi-scenarios and dashboards to compare the different alternatives

- Automatic optimization of the layout to target the best solution

- Incremental transformation by building your good solution manually

- A collaborative approach to facilitate the change management

Functions

Data and Building

- Use a simple picture of the factory blueprint to design the layout

- Optimize cell formation with a genetic algorithm

- Quickly identify machines operating below or above their capacity

- Create your filters (by-products, machines, operators, product families)

Analysis and Result

- Compare the scenarios within a dashboard

- Analyze aisles congestions and direct connections between machines

- Build and test any layout solutions thanks to the great interactivity

- Review the layout taking into account all the part-mix ratios, not Pareto because 20% of the products will generate 80% of perturbations

- Automatic identification of product families

Process

- The customer extracts his data from his ERP (or another database) to fill an Excel sheet, and a macro is used to transform it into an “XML file”

- The data can also directly be collected or changed through the SIMOGGA user interface

- The user creates the As-Is situation with SIMOGGA, and the data is validated thanks to the visual view

- The user analyzes the data using SIMOGGA solutions to generate an efficient factory layout

- A graphical view to make the flow analysis without any constraints (technical, historical,

- the production (demand variation, new product, new mix product…)

- High interactivity to capture the input of the operators and create a consensus

- The plant manager chooses the solution that fits his needs

- The changes are explained and discussed collaboratively with each actor involved

Those steps can be done by the customer or with our help.

System Requirements

SIMOGGA is based on Qt framework and has been tested on the following platforms:

- Microsoft Windows 10, x86-32 and x64

- Microsoft Windows 8.1, x86-32 and x64

- Microsoft Windows 7 SP1, x86-32 and x64

- Microsoft Windows Vista SP2, x86-32 and x64

- Apple Mac OS X 10.9 (Maverick) or later, Universal

SIMOGGA may also be installed on other platforms not included in this list (such as other Mac OS or Windows distributions), but we cannot guarantee its full platform compatibility.

SIMOGGA installation requires 300MB of free disk space. We recommend having 4GB of memory and a modern processor for optimal performance. The mouse is typically preferable to the touchpad for graphical editing.