A visual simulator to analyze your data, give a visual representation and guide you to optimize the warehouse

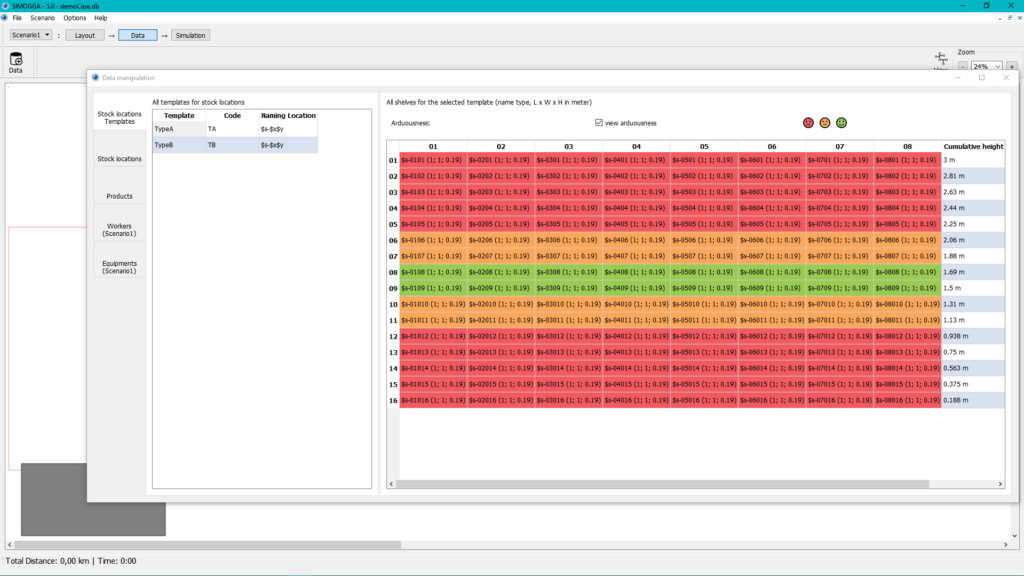

Shelves with arduousness

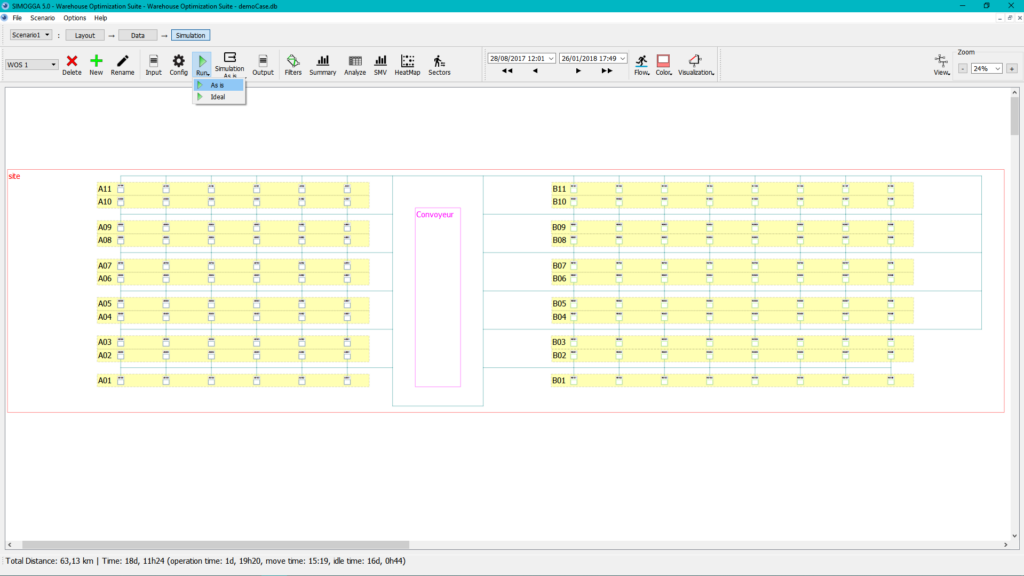

Flows in the warehouse

Improve the slotting

Decrease arduousness by 20 to 70 %

Decrease the analysis management time by 50 to 75%

Improve the flexibility and operational agility

Increase the efficiency of each actor

Human Benefits

- Quickly identify problems and create various solutions

- Accelerate the decision-making process and increase collaboration

- Reduce the arduousness of the work

- Increase agility by anticipating the variation of load and reacting against areas

- Involve teams thanks to the easy to use

User Benefits

- Support the Lean Team by quantifying the benefits of the improvement suggestions (Costs/Benefits analysis)

- Support the Logistical Team by offering a global view of the warehouse (flows and product and its efficiency)

- Support the strategy by simulating picking strategies before implementing the best ones (thanks to the comprehensive and operational parameters)

- Support the business controller by offering visual KPIs (efficiency by sectors, by operators….)

In the showcased video, we quickly describe the process used to analyze the efficiency of a warehouse and improve its performance by working on the stock locations and the picking strategy.

If you want more information or to understand how to solve a case with SIMOGGA fully, we recommend you watch one of our video tutorials.

More About SIMOGGA Analytics

Functions / Analysis and Result

- Easily and quickly create the layout with thousands of stock locations (based on templates)

- Create your filters (by products, machines, operators, product families)

- Simplify the flow analysis using filters to decrease the complexity

- Analyze the aisles congestion and remove it by changing the layout

- Create product families (Product Flow Analysis, ROC, Similarities)

- Quickly identify product locations with low, medium or high rotation

- Visualize highlighted row concentrating on the best improvements

- Quantify the required human resources to reach the goals

Process

- The customer extracts their data from an ERP/WMS (or another database) to fill in an Excel sheet to be transformed it into an “xml file”

- The data can be directly collected or changed through the SIMOGGA user interface

- The design of the layout is built in the Layout view to define the different storage and product location

- The data and its reliability can be validated thanks to the visual view of flows and storage

- Based on the historical picking data, the user creates the As-Is situation with SIMOGGA to analyze the current KPIs

- The As-Is view offers the flow analysis and an evaluation of all the KPIs (Arduousness, kilometers, efficiency…)

- The transport time is computed by the simulator (based on the layout) to extract the real picking time (by zones and workers)

- The user is guided in SIMOGGA to reach improvements and simulate various scenarios to generate an efficient warehouse

- A “quick compare” scenario interface to test and validate the changes in the warehouse (Product location, layout modification, picking strategy, demand variation, new products, new investment…)

- A high interactivity rate to capture the input of the operators and create a consensus

- The improvements can be spread over time and follow the reality on the field by inserting new data

System Requirements

SIMOGGA is based on Qt framework and has been tested on the following platforms:

- Microsoft Windows 10, x86-32 and x64

- Microsoft Windows 8.1, x86-32 and x64

- Microsoft Windows 7 SP1, x86-32 and x64

- Microsoft Windows Vista SP2, x86-32 and x64

- Apple Mac OS X 10.9 (Maverick) or later, Universal

SIMOGGA may also be installed on other platforms not included in this list (such as other Mac OS or Windows distributions), but we cannot guarantee its full platform compatibility.

SIMOGGA installation requires 300MB of free disk space. We recommend having 4GB of memory and a modern processor for optimal performance. The mouse is typically preferable to the touchpad for graphical editing.