SIMOGGA Layout Design

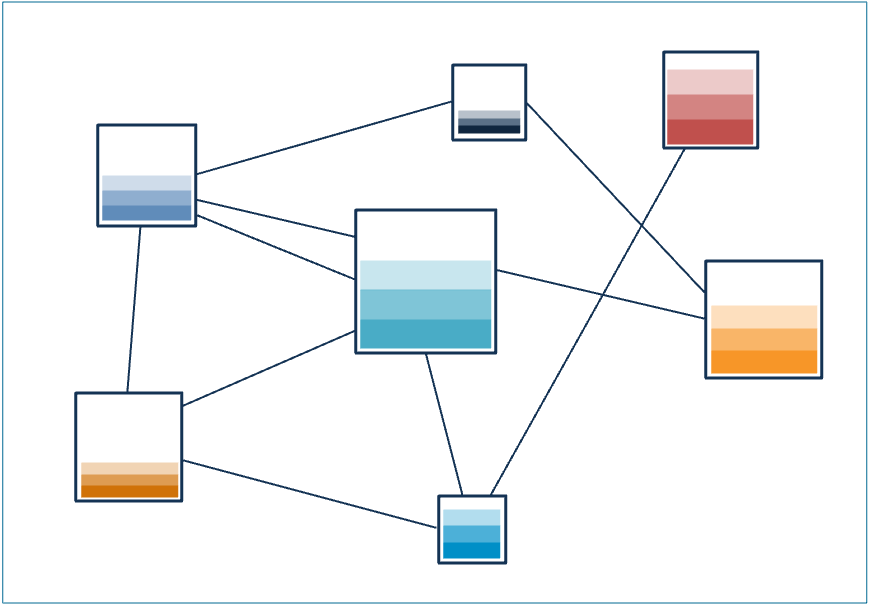

A graphical LEAN tool to visualize, quantify and optimize factory layout design based on global flow analysis

SIMOGGA Planner

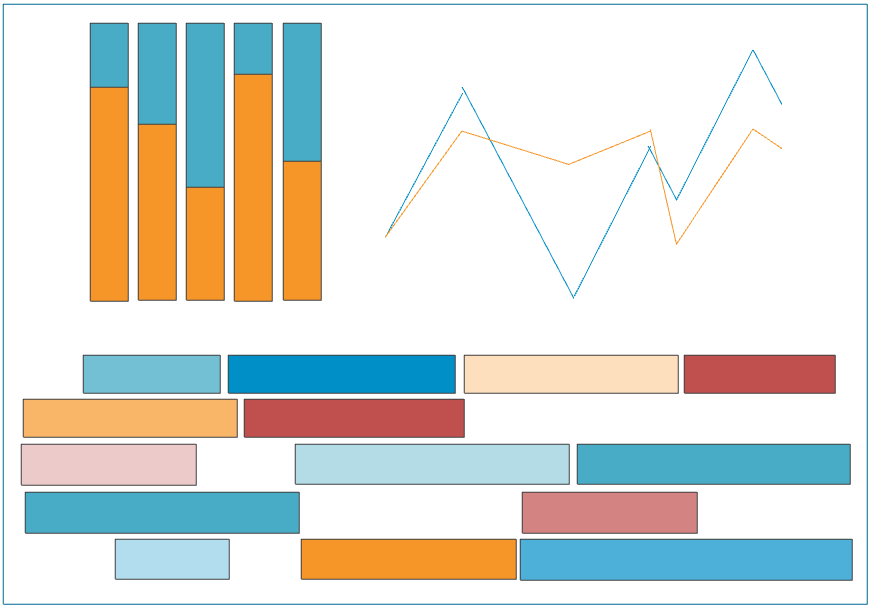

An advanced planning and scheduling software to visualize, quantify and optimize your production

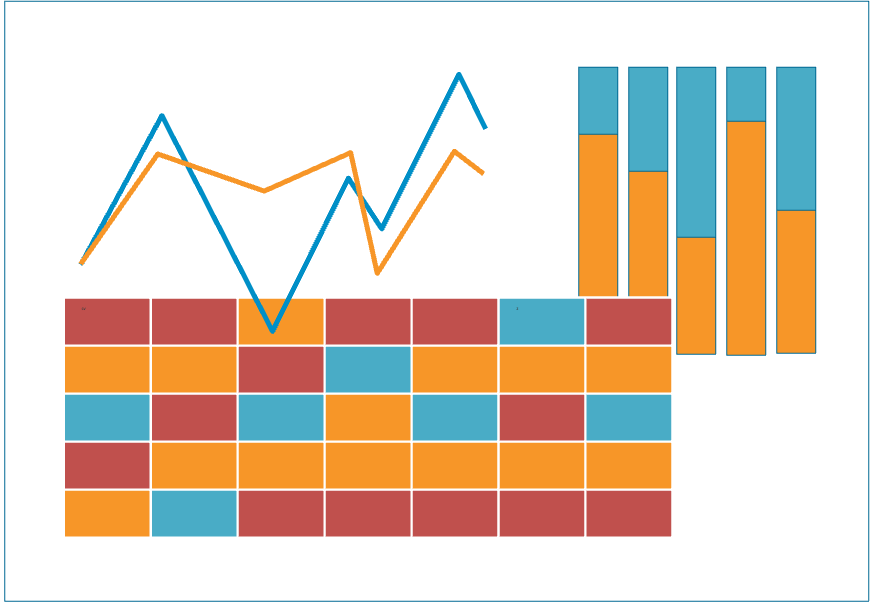

SIMOGGA Analytics

A visual simulator to analyze your data, give a visual representation and guide you to optimize the warehouse

Production – SIMOGGA Layout Design and SIMOGGA Planner

Lean software for a collaborative approach

Getting Started with SIMOGGA

Discover how to build a new case, optimize the flows, analyze the capacity (with material and human resources) and find/remove bottleneck to achieve the production

A complete use case with SIMOGGA

Discover how to use different functionalities of SIMOGGA from the data, the flow analysis until simulation (capacity and bottleneck detection)

And more

Warehouses – SIMOGGA Analytics

SIMOGGA Analytics is dedicated to the warehouses. How to continuously improve your efficiency?

This video shows how to create a new layout in SIMOGGA Analytics with the different rows, shelves, and stock locations through an import from excel.

After having designed the warehouse, defining the stock location with different templates of shelves.

Part 1 – 0:24 Expedition areas

Part 2 – 2:09 Stock location templates

Part 3 – 6:55 Stock locations

Part 4 – 8:30 Products

Part 5 – 9:05 Operators

Part 6 – 10:35 Virtual zones

Part 1 – 0:20 Simulation 1: The reference simulation

Part 2 – 2:23 Simulation 2: Products relocations (Critical swaps)

Part 3 – 6:07 Simulation 3: Products relocations (All)

Part 4 – 7:42 Simulation 4: Products relocations (Based on distance)

Part 5 – 10:38 Simulation 5: Group 2 operations by batch

Part 6 – 12:22 Simulation 6: 1 order by batch

Part 7 – 13:29 Simulation 7: Group 2 orders by batch

Part 8 – 14:31 Simulation 8: Group 3 orders by batch